Resin & FDM Printing for Miniature Wargaming: A Comparison of Costs and Material Usage

Posted on by Wargaming3D

As an Amazon Associate Wargaming3D.com will earn from qualifying purchases.

Recently I’ve been asked what it costs to print a model in FDM vs Printing it in Resin, as well as printing a hollowed vs solid model. Lots of prices get thrown around, but I haven’t really dug into how much it costs me in raw materials. So I thought I’d take a look at it and break down some of the costs. Please note that this doesn’t take into account power usage, wear and tear etc, as that will depend on printer, and the cost of power where you are locally, but it should at least give you a rough comparison. I’ve also been considering whether it’s worth hollowing models a lot of the time. It’s often suggested to hollow models to save resin, but I do prefer the weight of a solid model, so I decided to crunch some numbers to see if it was actually worth the time and effort hollowing, as I’ve noticed that the side effect can include seepage of uncured resin in a hollowed model, as for some it seems impossible to clean and cure them properly. Here’s the (unscientific() results I cam up with and they might surprise you! Please note that these are all based on the estimates given by the slicer, so I cannot voice for their accuracy, I’ve disregarded any of their own price calculations and done them myself based on the following assumptions:- 1 x Bottle of 500ml Anycubic Resin on Amazon: $29.99 USD (0.05998c per ml)

- 1 x Bottle of 1000ml Anycubic Resin on Amazon: $58.99 USD (0.5999c per mil)

- 1 x Spool of 1kg Hatchbox PLA on Amazon: $19.99 USD (0.01999c per gram)

m_bergman Bren Carrier – 1/56 and 1/100

- 1/56 Bren Carrier – FDM, Fine (0.1mm) 10% Infill, 2mm Raft, Supports Touching Build Plate: 7.17m/21g (Cost: $0.41)

- 1/56 Bren Carrier – Resin (Green Anycubic), Supports, Angle 10%,Solid: ~32.8ml Resin, 36.1g (Cost: approximately $1.97)

- 1/56 Bren Carrier – Resin (Green Anycubic), Supports, Angle 10%, Hollow (2mm thickness): ~32ml Resin, 36g (Cost: approximately $1.91)

- 1/100 Bren Carrier – FDM, Fine (0.1mm) 10% Infill, 2mm Raft, Supports Touching Build Plate: 1.78m/5g (Cost: approximately $0.10)

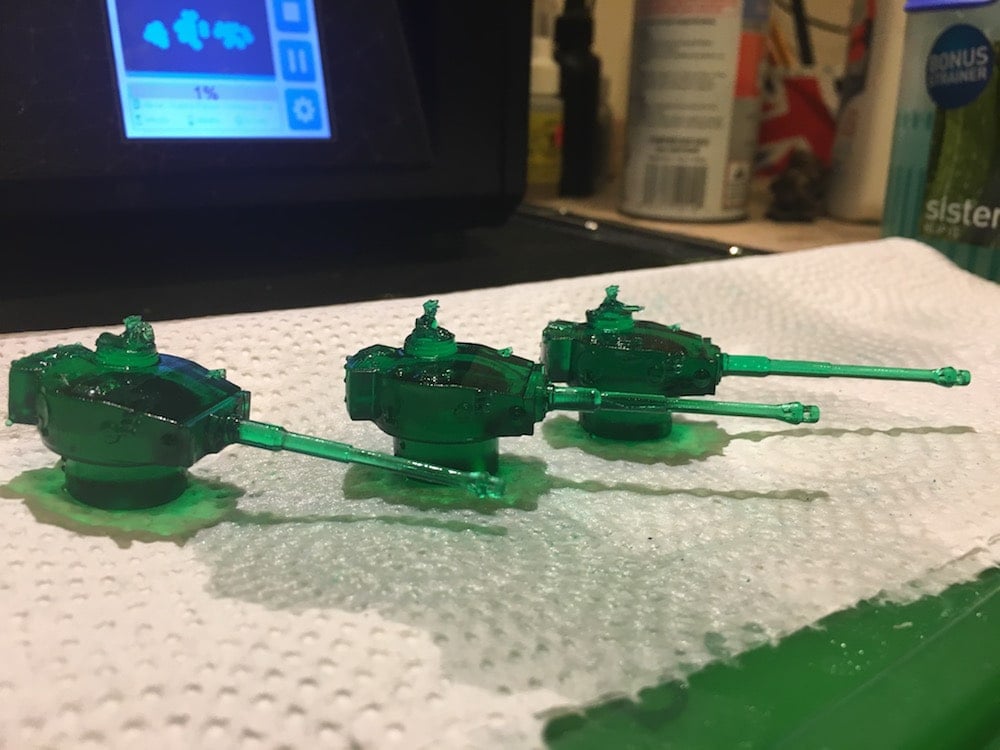

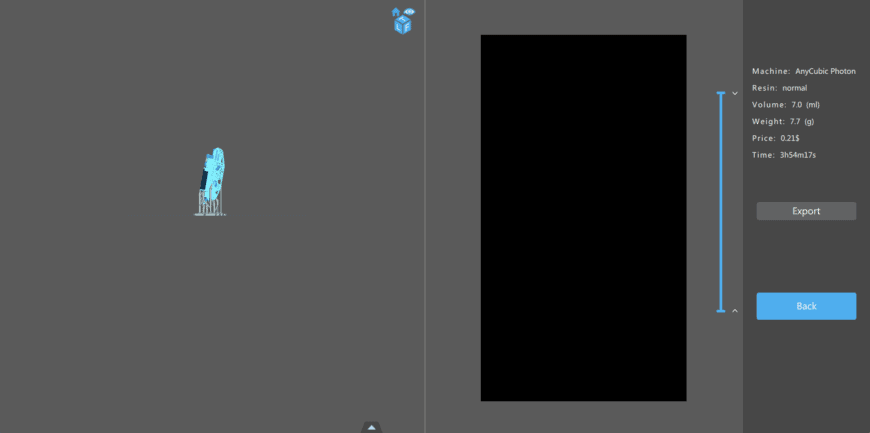

- 1/100 Bren Carrier – Resin (Green Anycubic), Supports, Angle 10%. Solid: ~7ml Resin, 7.7g (Cost: approximately $0.42)

- 1/100 Bren Carrier – Resin (Green Anycubic), Supports, Angle 10%, Hollow (2mm thickness): ~7ml Resin, 7.7g (Cost: approximately $0.42)

m_bergman – Tiger

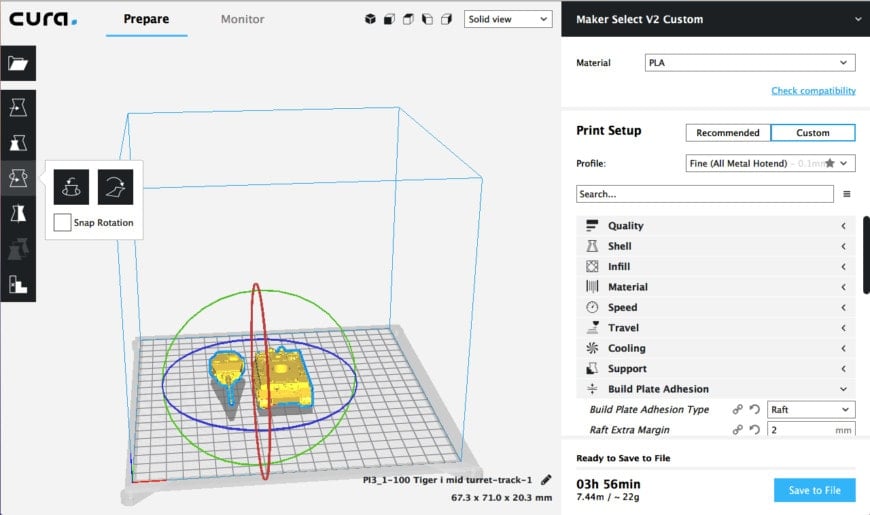

- 1/100 Tiger – FDM, 2mm Raft,Fine (0.1mm) 10% Infill, Supports Touching Build Plate: 7.44m/22g (Cost: approximately $0.43)

- 1/100 Tiger Resin (Green Anycubic), Supports, Angle 10%. Solid: ~37.7ml/41.5g (Cost: approximately $2.26)

- 1/100 Tiger – Resin (Green Anycubic), Supports, Angle 10%, Hollow (2mm thickness): 28.2ml/31.0g (Cost: approximately $1.69)

- 1/100 Tiger – Resin (Green Anycubic), Supports, Angle 10%, Hollow (1.5mmmm thickness): 24.1ml/26.5g (Cost: approximately $1.46)

TigerAce1945 – E-100 StuG

- 1/100 Stug e100 – FDM, 2mm Raft, Fine (0.1mm) 10% Infill, Supports Touching Build Plate: 9.56m/29g (Cost: approximately $0.57)

- 1/100 Stug e100 – Resin (Green Anycubic), Supports, Angle 10%. Solid: 54.1ml/59.5g (Cost: approximately $3.24)

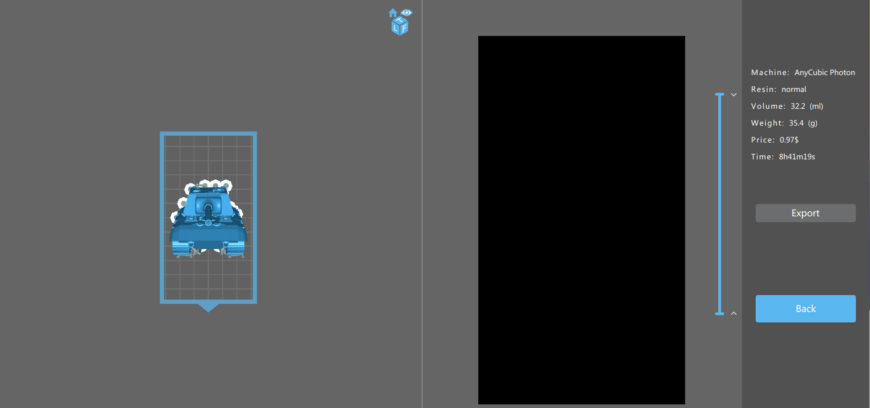

- 1/100 Stug e100 – Resin (Green Anycubic), Supports, Angle 10%, Hollow (2mm thickness): ~32.2ml/35.4g (Cost: approximately $1.93)

- 1/100 Stug e100 – Resin (Green Anycubic), Supports, Angle 10%, Hollow (1.5mmmm thickness): ~28.5ml/31.3g (Cost: approximately: $1.70)